Metal Fabrication Malaysia | Industrial Equipment & Part

- Aathaworld Sdn Bhd

- Dec 24, 2017

- 5 min read

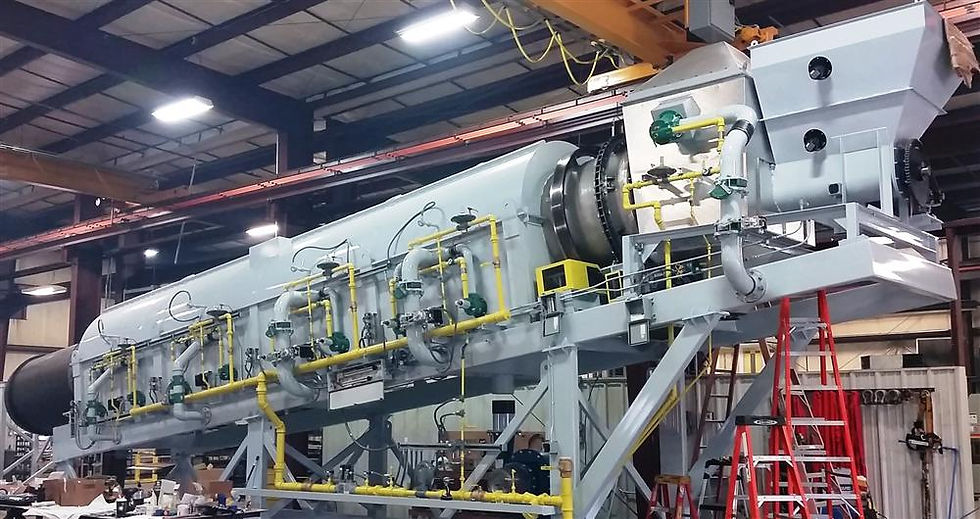

Metal fabrication in Malaysia involves several industrial process such as shaping, cutting, drilling, moulding of metal raw materials into finished ready-to-use metal products. Without a doubt, among metal categories, steel has the most popularity in metal custom made fabrication in Malaysia. From building material, industrial equipment, structural to loose metal accessories application, steel is widely being seen and utilized in factory operation, infrastructure to building elements. Hence, metal fabrication Malaysia is so important and the number of metal fabrication supplier in Malaysia grows every year to meet the increased demand in metal products series.

Metal is tough yet versatile in application and industries dimensionally; metal fabrication Malaysia covers from metal sheet, metal bars, metal rods, metal tank, metal pipe to many others. Custom made fabrication services can be done by metal fabricator Malaysia, in term of design consultancy and manufacturing aid. Made-to-design, built-to-order parts service are a must capabilities acquired by metal fabrication factory in Malaysia.

Design and Engineering

Custom metal fabrication services Malaysia are extremely important for the product development stages, either from an individual component fabrication to complete manufacturing production. The phases are comprised of the design or R&D, manufacturing, finalizing and assembly before delivery. Design or Research and Development (R&D) stage is a very crucial beginning to the metal fabrication, it is applicable to new requirement but yet this stage does not always apply. It involves the forming of product features or part functionalities, including modification of existing product system. Metal fabricator in Malaysia has to be competitive enough as in having a full team in design and engineering, re-engineering, fabrication, assembly and installation in order to gain a reasonable market share in the heavy industry.

Manufacturer of metal fabrication Malaysia should have also wide machineries such as lathe, milling, turning, drilling, shaper, broaching, grinding, planer and many more. These machineries help to complete complex manufacturing process, for example, turning machine can do lathe, facing, boring, spinning, kurling and cutoff. Lathe in metalworking for instance, involves the workpiece removal by applying hardened cutting tool, in which it is being mounted on a solid moveable base apparatus. It can be controlled by handwheel or computerized motor (computer numerical control, CNC). The cutting tools come in square, diamond, triangular and round in order to produce extensive shapes and sizes.

Metalwork and Fabrication

Industry of metal fabrication in Malaysia has been around for more than hundred years, especially lathe machine which helps to produce numerous machine parts and its maintenance repair works. As metal fabrication demand grows, there is a need to enhance the production speed by having more machines and labour force; However, it will not be the case due to the hiked machine and labor cost without an underlayment support from metal parts market selling price. Therefore, CNC lathe was introduced to the metal fabrication Malaysia as technology advances to solve these problems. CNC machine fabrication in Malaysia enable wider range of metal product type can be lathed, the production volume can be enhanced in comparison with manual lathe machine. In addition to this, it makes Malaysia metal fabrication services more competitive in worldwide market, higher productivity and economies of scale lower the cost, subsequently improve the precision level.

CNC lathe machine allows less experienced factory worker can operate smoothly through a comfortable level understanding of how the machine works. Complicated cutting and other type of tasks on metal fabrication Malaysia can be done by using CNC lathe machine, the only limitation only happens when manual machine is used. Besides accuracy and consistency, the production cost of using CNC lathe machine also reduced through lesser rejected, return, redo finished products.

Metal Finishing

Metal product exterior must be treated with proper finishing process, to protect it or its related components, appearance, safety, lifespan, preventing its resistance time to wear and tear. In details besides durability, metal fabricator Malaysia should always carry out metal finishing since it can enhance resistance to electrical (or improve electrical conductivity), resistance to chemical and decorative appearance. Metal finishing is inclusive of plating, brushed, buff, grinding, vibratory, sand blasting, powder coating and hot blackening.

Metal fabricator Malaysia applies chemical bath coat to alter the substrate surface through a metal thin layer, including PTFE or nickel as well as the utilization of electroplating method; this increase the corrosion resistance, durability, surface appearance and frictionally but not applicable in defects smoothening. Brushed metal is suitable to be used on surface flaw elimination, identical parallel grain textured surface will be created on exterior’s smoothness through wire brush or abrasive belt. Buff polishing on another hand is to generate a non-textured smooth finishing, cloth wheel can be used to buff into glossy surface (but not encourage to be applied on crumbly, recessed and intricate features).

There are also other types of finishing method can be done by metal fabricator in Malaysia including metal grinding, vibratory finishing on sharp edges polish, sandblasting on soft metal, powder coating for greater durability or surface defect removal as well as hot blackening for resistance requirement to high abrasion with matte black finish.

Assembly & Installation

Last but not least, metal fabricator Malaysia will either finish the assembly off-site and in their own yard or install at client’s site (plant or building). After-sale warranty and maintenance shall also be provided to client to ensure client is worry-less to purchase the product and service from the fabricator.

Where to Get Fabricator and Engineering Factory in Malaysia

Aathaworld Sdn Bhd can supply many types of metal, steel and other custom made fabrication for indoor and outdoor, construction, consumer goods, industrial, light and heavy industrial usage, plant and factories, decorative façade, customizable specification to make sure you have the best quality fabrication and supply in Malaysia to fit your requirement. As a custom made metal fabrication supplier and metal fabrication specialist in Malaysia, we are able to provide customize specification, stainless steel, mild steel, sheet metal, precision metal fabrication, piping fabrication, bolt and nut fabrication, gear fabrication, flanges fabrication, steel plate rolling, welding, turning, boring, drilling, cutting, polishing, fabrication and materials supply for your requirement or projects in KL Kuala Lumpur, Selangor, Klang Valley, JB Johor Bahru, Penang, Malacca (Melaka), Seremban Negeri Sembilan, Perak, Pahang, Kuantan, Kelantan, Terengganu, Perlis, Alor Setar Kedah, as well as Sabah and Sarawak for East Malaysia; besides Malaysia, we are also able to be metal fabrication supplier for other countries in Southeast Asia (SEA) such as Singapore, Cambodia, Vietnam, Laos, Myanmar (Burma), Thailand, Indonesia, Philippines, Brunei.

Submit your metal fabrication sourcing requirements either you are looking for a metal building material supplier in KL Kuala Lumpur, Selangor or other states in Malaysia. Purchase your metal product Malaysia today, submit your enquiry to us today at info@aathaworld.com or call (whatsapp) to +(60)11-7001 1003 (Monday to Friday) or +(60)11-1188 1003 (Saturday, Sunday & Public Holiday).

Photo credit: artisticalloys, thermalenergyinc, alibaba, k-mm, thefabricator, metalfabwi, bsmw, dura-bond, seradex, energomontage-bs, superiorjetties, smartfab

Comments