Acrylic Tube

- Sep 17, 2017

- 5 min read

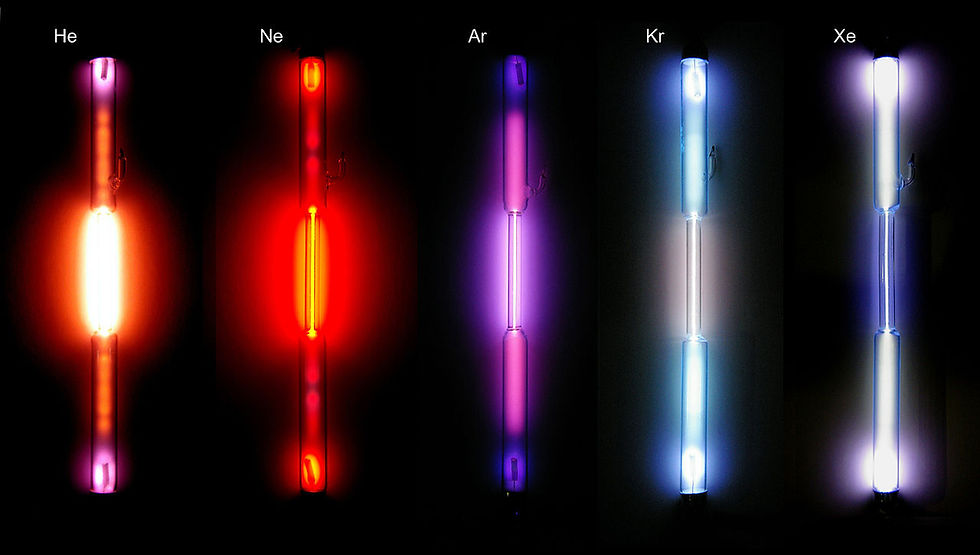

Many industries are now replacing acrylic tube as an alternative to glass tube or any other material types of tube for their application. Normally in USA people called them as Plexiglas or Plexi while Europe consumers commonly named the as Perspex; in Malaysia acrylic tube is also widely titled as Perspex tube or acrylic tube.

Today, besides presenting the advantages of acrylic tube to you, we are also pleased to get you informed also on the details of acrylic types available for tube and why you should also always go for acrylic materials when you are getting tubing.

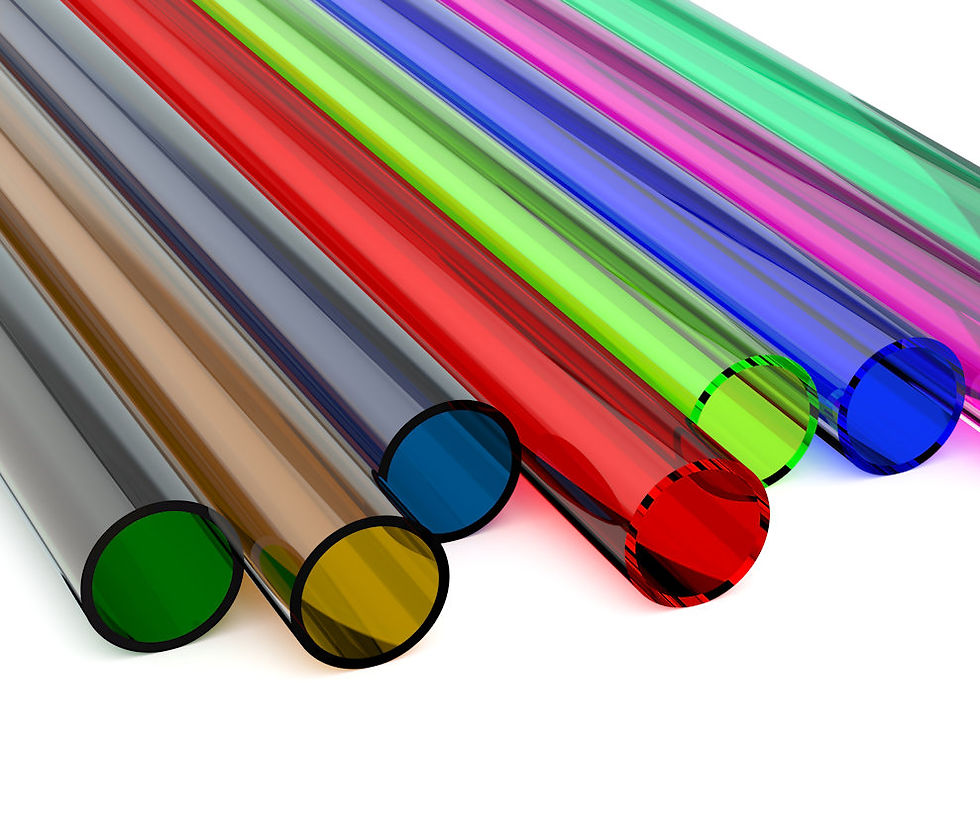

Acrylic tube is made by polymer from carbon molecules that have been further combined chemically to shape into tube or cylinder. The tubing’s physical attributes are created by casting or extruding the resin where we can further classify them into either extruded acrylic tube or cast acrylic tube. These two versions have only some major difference in production process which is then cause them to fall under two diverse categories.

Cast Acrylic Tube versus Extruded Acrylic Tube

Cast acrylic tube manufacturer in Malaysia normally blend the fluid form of elements into a preset mould, in this case is the cylinder shape. The chemical process allows the properties to be identical in all directions. While the extruded acrylic tube supplier in Malaysia produces extrusion type of acrylic tube in a different way, they push the acrylic mass continuously through a form.

Acrylic tube supplier Malaysia claims that cast acrylic has better quality than extruded acrylic tube due to its resistant level to various solvents, in another word, greater chemical resistance. When it comes to laser cutting and engraving, cast acrylic will show no burrs and matt white while extruded acrylic tube has some burr on one side and seem to have some matt gray.

Heat bending and thermoforming make no difference to cast acrylic and extruded acrylic tube tends to act differently in term of direction and colour. The next issue is on the thickness tolerance where it is more relevant to acrylic sheet instead of tube, 15% variance versus 5% respective to cast and extruded acrylic tubes. Furthermore, acrylic tube supplier in Malaysia also claims that the resistance level to scratch, flame polish and tensile strength of cast acrylic are better extruded acrylic.

Acrylic Tube Supplier in Malaysia

Cast acrylic supplier in Malaysia may not be doing better than extruded acrylic supplier in Malaysia, the main reason is pretty simple; because cast acrylic tube is much more expensive than extruded although it has higher quality in term of stability against thermal and chemical substances. Consumers in Malaysia will go for extruded acrylic sheet, extruded acrylic box, extruded acrylic tube or extruded acrylic rod when they need to buy acrylic products (i.e. acrylic tube) online or offline in Malaysia.

The other benefits of why purchaser is looking for extruded acrylic tube in Malaysia is because it has thickness consistency and suitable for multiple application since the fabrication can be full of varieties. Extruded acrylic tube is tougher and therefore it can tolerant high temperature and less prone to bending. Flame polish can let extruded acrylic to bonds better when apply different chemicals, in another term, more malleable.

Since the major value proposition of acrylic tube is as an alternative to glass tube, so the most important advantage is the impact resistant of acrylic tube. Acrylic tube supplier in Malaysia therefore sell more extruded acrylic tube than cast acrylic tube since these type of acrylic is ten times better than glass in the aspect of impact resistance. Most importantly, the durability, surface toughness, virtually shatter-proof, exceptional UV stability are the same when you opt for extruded or cast acrylic from acrylic supplier in Malaysia.

Application of Acrylic Tubes

Acrylic can be shaped into wide range of sizes and shape with high temperature, highly durable in adverse weather and environment, hence acrylic tube in Malaysia has extensive coverage in term of application regardless of indoor or outdoor. Acrylic tubes supplier in Malaysia able to offer higher resilience compared to multiple plastic types of tubes.

Many opt to go for acrylic tube supplier Malaysia instead of other tubes in their usage also because it can last for minimum 10 years, without affecting the colour and clarity and especially for those who looks for high weatherability material such as sunlight, at the same time the material does not compromise in light remittance level reduction.

Moreover, it has also higher heat insulation, at least 20 percent better than glass with non-clouding and non-yellowish features. Acrylic tube supplier Malaysia is able to custom make and supply the acrylic tubes to users in school lab, education, agriculture, aquarium or aquaculture, chemical, home, garden, marine, medical, manufacturing, transportation, advertisement, design, building and construction.

Perspex Tube or Acrylic Tube Supplier Malaysia

Affordable acrylic in Malaysia enables user who need it in large quantities can afford to buy. Clear acrylic tube supplier also known as perspex tube supplier in Malaysia are able to provide glazed, non-glazed, flexible clear plastic tube material which is appropriate for application such as lab test, medical experiment, mock up unit, school project, DIY project, design decoration or retail display, point of sale (purchase), lighting as well as shop display shelf or rack.

Additionally, acrylic tube manufacturer in Malaysia are easy to work with or fabricate acrylic tube or acrylic rod due to its workability, low raw materials cost and of course sustainable demand in acrylic market. Compared to all the thermoplastic materials in Malaysia market, cast or extruded acrylic, solid or transparent colour, fluorescent, rosted or clear acrylic tube or rod, polycarbonate tube or rod, test tube, perspex tube, perspex rod, Plexiglas (plexiglass) are measured as one of the stiffest pleasing material. Above and beyond that, low cost acrylic tube (rod) supplier in Malaysia can produce cost-effective extraordinary quality plastic tube or plastic rod materials. Its modest manufacturing process, less fragile than glass and recyclable eco-friendly features also make acrylic tube is a more preferred to be used.

Where to buy acrylic tube in Malaysia? Don’t worry, Aathaworld Sdn Bhd are here to help you, submit your design or special acrylic requirement enquiry to us for quotation today, either you are looking for clear, or coloured acrylic tube or acrylic rod with different thickness, inner diameter (ID) or outer diameter (OD) and length (we can laser cut also besides standard acrylic length 2m and 1.2m). Enquire at info@aathaworld.com or call (whatsapp) to +(60)11-7001 1003 (Monday to Friday) or +(60)11-1188 1003 (Saturday, Sunday & Public Holiday). to get an acrylic idea in Malaysia with us, bring to you by Aathaworld Sdn Bhd, one of the best acrylic supplier in Malaysia.

Photo credit: coloredplastics, australiansheettraders, aliexpress, eplastics, archplastics, lightfurnitures, decoist, akailochiclife, commons.wikimedia, in-pharmatechnologist, archiexpo, biz-on,

Comments